Introduction:

The Gold Bonding Wire for Semiconductor Packaging market Size is expected to grow USD 7.2 Billion by 2032, at (CAGR) of 6.20% during the forecast period (2023 - 2032).

In the world of semiconductor packaging, every component plays a crucial role in ensuring the reliability, performance, and longevity of electronic devices. Among these components, gold bonding wire stands out as a cornerstone of connectivity, providing the vital link between semiconductor chips and their packaging. In this article, we delve into the dynamic landscape of the gold bonding wire market, examining its significance, key trends, and future prospects.

Understanding Gold Bonding Wire:

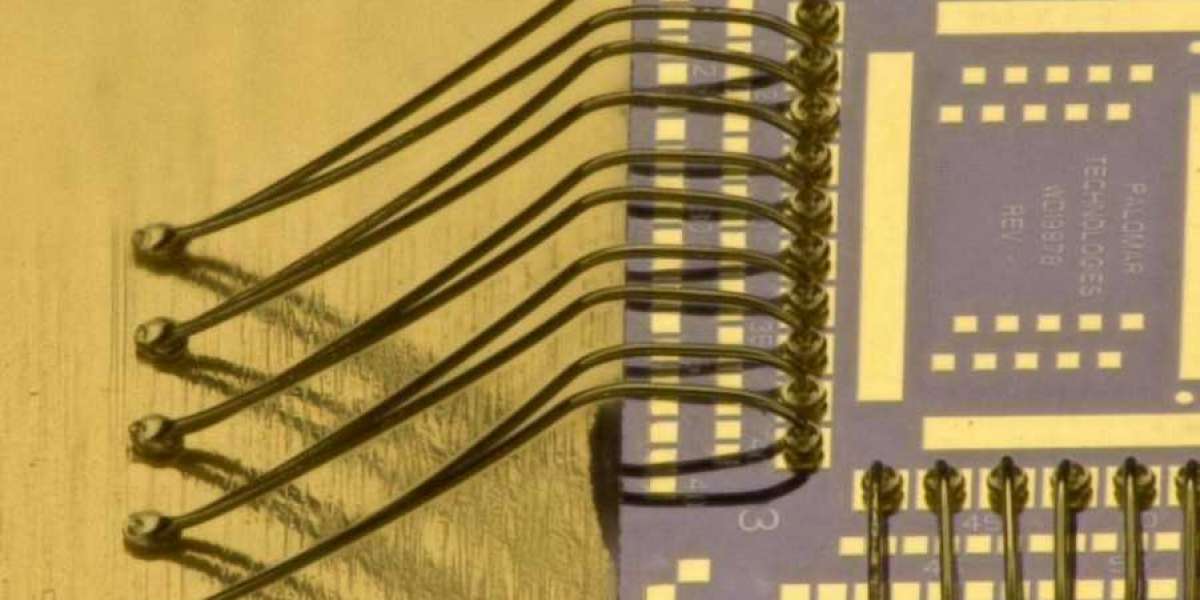

Gold bonding wire serves as the primary interconnect material in semiconductor packaging, facilitating the electrical connection between the semiconductor die and the package substrate. It is typically made from high-purity gold and is available in various diameters and compositions to meet the specific requirements of different semiconductor applications. Gold bonding wire is widely favored for its excellent electrical conductivity, corrosion resistance, and reliability, making it a preferred choice for high-performance semiconductor devices.

- Superior Electrical Conductivity: Gold boasts exceptional electrical conductivity, allowing for efficient transmission of signals and currents within semiconductor devices. Gold bonding wire ensures low resistance connections, minimizing signal loss and enhancing device performance.

- Corrosion Resistance: Gold is inherently resistant to corrosion and oxidation, ensuring long-term reliability and stability of semiconductor connections. This resistance to environmental factors makes gold bonding wire particularly suitable for applications requiring extended device lifetimes and harsh operating conditions.

- Wire Bondability: Gold bonding wire exhibits excellent bondability characteristics, enabling reliable wire bonding processes during semiconductor assembly. Its malleability and ductility allow for precise wire bonding onto semiconductor pads, ensuring strong and durable connections.

- Compatibility with Various Substrates: Gold bonding wire is compatible with a wide range of substrate materials commonly used in semiconductor packaging, including aluminum, copper, and gold-plated surfaces. This versatility enables its use in diverse packaging configurations and assembly processes.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/12626

Gold Bonding Wire for Semiconductor Packaging market Companies include:

- Heraeus

- Tanaka,

- NIPPON STEEL Chemical Material

- Tatsuta, MK Electron

- Yantai Yesdo

- Ningbo Kangqiang Electronics

- Beijing Dabo Nonferrous Metal

- Yantai Zhaojin Confort

- Shanghai Wonsung Alloy Material

- MATFRON

- Niche-Tech Semiconductor Materials

Market Applications:

The demand for gold bonding wire is driven by its widespread adoption across various semiconductor applications, including:

- Integrated Circuits (ICs): Gold bonding wire share is extensively used in the assembly of integrated circuits, where it provides the critical electrical connections between the semiconductor die and the lead frame or substrate. ICs manufactured for a broad spectrum of industries, including consumer electronics, automotive, telecommunications, and aerospace, rely on gold bonding wire for high-reliability packaging solutions.

- Light-Emitting Diodes (LEDs): In LED manufacturing, gold bonding wire plays a vital role in connecting the LED chip to the package, enabling efficient electrical and thermal management. The superior conductivity and reliability of gold bonding wire contribute to the performance, brightness, and longevity of LED lighting products.

- Power Devices: Gold bonding wire is utilized in power semiconductor devices such as MOSFETs, IGBTs, and diodes, where it facilitates robust electrical connections in high-power applications. Power devices requiring efficient heat dissipation and low resistance connections benefit from the superior characteristics of gold bonding wire.

- MEMS and Sensors: Microelectromechanical systems (MEMS) and sensor devices rely on gold bonding wire for precise interconnections and signal transmission. Gold bonding wire enables the integration of sensors into various electronic systems, including smartphones, wearable devices, and industrial sensors, where reliability and miniaturization are paramount.

Gold bonding wire Market Analysis:

The gold bonding wire market is poised for steady growth, driven by the continuous evolution of semiconductor technologies, increasing demand for miniaturized electronic devices, and expanding applications in emerging industries such as IoT, 5G, and electric vehicles. Despite the emergence of alternative bonding technologies such as copper and silver, gold bonding wire remains irreplaceable in many high-reliability semiconductor applications due to its unmatched performance and reliability.

Get a regional report for US gold bonding wire market