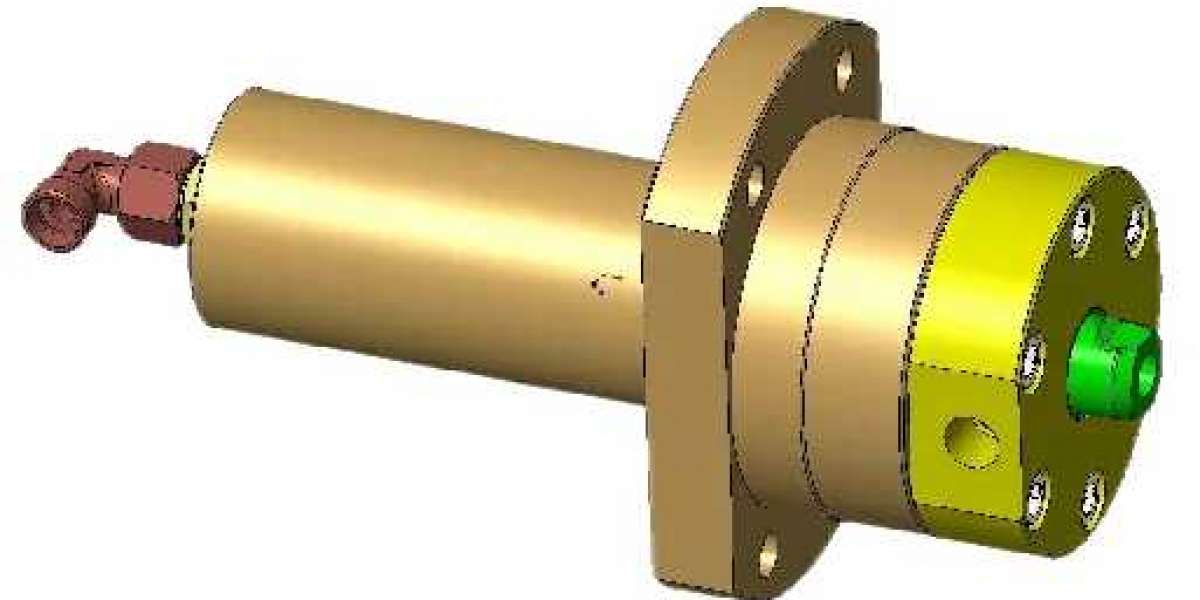

Tie rod cylinders are important components in hydraulic systems and are used to convert fluid power into linear mechanical force. They are commonly used in a variety of industrial applications, including construction equipment, agricultural machinery, and manufacturing processes. However, like any other hydraulic component, tie rod cylinders are susceptible to corrosion, which can lead to reduced performance, damage, or even failure. In this article, we will discuss some anti-corrosion measures you can take to ensure the longevity and reliability of tie rod cylinders.

Material selection

The first and most critical step in preventing corrosion on tie rod cylinders is choosing the right materials. The cylinder block and end cover should be made of corrosion-resistant materials such as stainless steel or aluminum. The piston rod should also be made of corrosion-resistant material, such as chrome-plated steel. Seals and bearings should be made of materials that are compatible with the hydraulic fluid and resistant to corrosion.

Surface treatment

Surface treatment is another effective way to prevent corrosion on tie rod cylinders. Cylinder blocks and end caps can be treated with protective coatings, such as anodizing or electroplating, to create a barrier between the metal and the environment. The piston rod can also be chrome-plated or ceramic-coated for extra protection against corrosion. The surface treatment should be selected based on the specific application and use environment of the cylinder.

Proper maintenance

Proper maintenance is essential to prevent tie rod cylinders from corroding. Cylinders should be cleaned regularly to remove dirt or debris that may promote corrosion. Hydraulic oil should be checked regularly and replaced according to the manufacturer's recommendations. It's also important to make sure the hydraulic fluid is at the correct level and the filter is clean and working properly. Any leaks or damage should be addressed immediately to prevent corrosion from spreading.

Environmental control

Environmental control is another effective way to prevent corrosion on tie rod cylinders. Cylinders should be protected from moisture, salt, and other corrosive substances. If the cylinder is used in a harsh environment, such as marine or coastal applications, additional measures may be required, such as the use of protective caps or the application of corrosion inhibitors. It is also important to ensure that cylinders are not exposed to extreme temperatures or humidity that could promote corrosion.

Corrosion inhibitor

Corrosion inhibitors are compounds that can be added to hydraulic fluids to prevent corrosion of tie rod cylinders. The function of these inhibitors is to form a protective film on the metal surface to prevent corrosive substances from coming into contact with the metal. Corrosion inhibitors should be selected based on the specific application and the type of hydraulic fluid used. Manufacturer's recommendations for the proper use and concentration of corrosion inhibitors must be followed.

In short, tie rod cylinders are an important part of the hydraulic system, and their life and reliability depend on effective anti-corrosion measures. Material selection, surface preparation, proper maintenance, environmental controls, and corrosion inhibitors are all effective ways to prevent corrosion on tie rod cylinders. By taking these steps, you can ensure that tie rod cylinders operate reliably and efficiently, providing long-lasting performance for your industrial applications.

https://www.toringcylinder.com/Protect-your-investment-effective-anti-corrosion-measures-for-tie-rod-cylinders.html