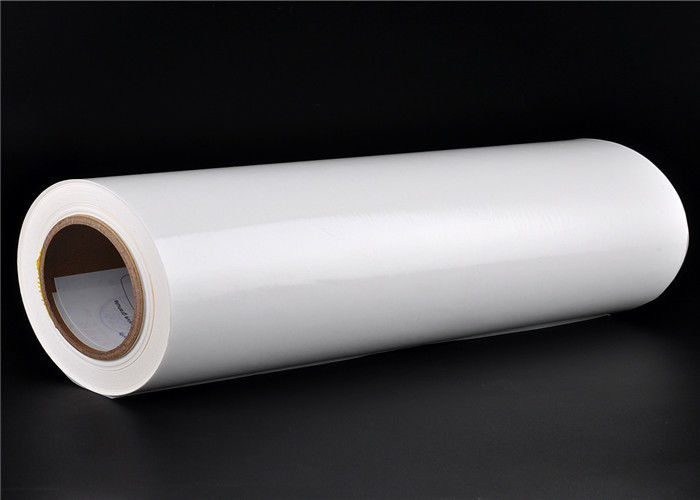

Stick of hot melt glue This product is white and opaque, non-toxic, easy to operate, and there is no carbonization phenomenon in continuous use. Additionally, there is no carbonization phenomenon. It bonds quickly, has a high strength, is resistant to aging, is non-toxic, has good thermal stability, and has the toughness of a film. Weigh the raw materials to match the formula ratio of the hot melt glue stick, then add them to the reaction kettle. Heat the mixture until it melts, and stir it until it is uniform. The rubber that has been melted in the reactor should then be cooled Low-melting point TPU adhesive film to a certain temperature before being put into the extruder that is operating. The speed of the extruder's output can be adjusted to match the characteristics of the rubber being processed. A round hole that protrudes from the top of the head and feeds into the sink.

The hot melt adhesive is immediately shaped when it comes into contact with the cooling water; the glue stick is initially cooled and shaped through the first cooling water tank; after that, it is drawn by the tractor into the second cooling water tank. The glue sample is completely cooled and shaped in the second cooling water tank, and the running speed of the glue stick in the water tank is controlled by the extrusion speed of the extruder. This ensures that the traction speed of the tractor and the extrusion speed of the extruder are synchronized with one another.

After adjusting and controlling the relationship between the extrusion speed, the cooling and setting speed, and the traction speed, the cooled glue stick must be cut and packed into finished products before proceeding. A quick look at the question of whether or not hot melt adhesives can prevent water leaks. A quick look at the question of whether or not hot melt adhesives can prevent water leaks. The use of hot melt adhesives in water is not recommended. There are many uses for hot melt adhesives, and in many of those uses, water will cause the adhesives to lose their original bonding ability. However, this is not always the case. In order to stop water from leaking through, hot melt adhesives have to be allowed to dry completely before the glue can be used up.

The fluidity of water is second to none, thermoplastic adhesive film and it can even approach the level of pervasiveness. In such a scenario, if the hot melt adhesive wants to stop water from leaking out, it will need to shield any and all gaps and through holes in the material. It appears to be very challenging to accomplish this with hot melt adhesive, based on our observations. Is there a way that it can be solved?——There is still a way to accomplish this challenging task of stopping leaks, despite the fact that the conditions that are applicable are very harsh.

According to our previous observations, the use of hot melt adhesives in environments containing water results in poor adhesion. Have you ever pondered the reasons behind why they are unable to adhere effectively?To put it another way, there is a wide variety of glue available for use in the process of adhering materials together. The use of hot melt adhesives can cover a relatively large variety of applications, making them one of the most versatile types of glue. However, there is a significant flaw in the rubber products that are so well known in the industry, and that flaw is the fact that they are terrified of water. How is it possible for hot melt glue to be so susceptible to damage when exposed to water when even regular glue has some degree of resistance to water?The reason for this is that the atomic composition of hot melt adhesives is far too variable to be useful. It should come as no surprise that temperature has an effect on hot melt adhesive, and that a change in temperature can actually affect the performance of hot melt adhesive itself.

It can be seen that the shielding ability of hot melt adhesive, based on its own performance, is very weak, and that it is completely changed by external influences. On the surface of the hot melt adhesive, water can easily penetrate and cause problems. After it has been made water-compatible, the body of the hot melt adhesive will undergo a change, and its performance will also be affected and altered; as a result, the hot melt adhesive will no longer be resistant to water.

However, the outcomes will be quite different if the hot melt adhesive undergoes a destructive fusion with the material before it comes into contact with water. The destructive fusion has the potential to make the molecules of the hot melt adhesive and the material intertwined in a large area and not oriented, which will directly destroy the molecular structure of the hot www.cn-hma.com melt collagen original, greatly reducing or even cutting off the influence of external factors on it, and resulting in the hot melt The state after glue bonding has become more stable than it has ever been. It is only under these circumstances that the hot melt glue will be able to block all of the through holes and gaps, cause the water to lose its flow, and contribute to the prevention of water leakage.

Use the strong plasticity of the hot melt adhesive if the material cannot be destructively fused with the hot melt adhesive. In addition, if the material cannot be fused destructively with the hot melt adhesive. In spite of the fact that it does not adhere, provided that it is a genuine hot-melt adhesive, it will definitely solidify. Make use of this function to obstruct At the water outlet, there is the possibility of achieving the effect of preventing water leakage, but it requires additional practice in actual operation.

In the process of selecting hot melt rubber particles, what kinds of methods do you typically have at your disposal?One variety of adhesive made of plastic is known as hot-melt glue. Within a certain temperature range, a change in temperature will cause a change in the hot-melt glue's chemical properties, but the change in temperature will not affect the glue's physical state. The hot-melt glue is completely safe to use and has no flavor. A variety of eco-friendly glue products can be found in this category. Particles made of hot-melt rubber have applications in the packaging of a variety of different industries. Hot-melt rubber particles are put into a hot-melt adhesive machine, where the heat from the machine is used to melt the hot-melt adhesive. Once the glue has been melted, it takes the form of a liquid. It is delivered to the surface of the object that is being adhered by the hot-melt adhesive machine's hot-melt adhesive tube and hot-melt glue gun. After reaching the surface of the adhered object, the hot-melt adhesive is cooled to finish the bonding process.

There should be some variation in the color specifications for the glue. Yellow hot melt glue is the one that should be used whenever there are no specific color requirements imposed by the object that is being repaired. In general, yellow hot melt adhesive is treated on the surface of the object it is adhered to because its viscosity is higher than that of white hot melt adhesive. Hot-melt adhesives on the surface of the bonded object are not as stringent as other adhesives on the surface of the bonded object; however, the dust and oil stains on the surface of the bonded object should also be properly treated in order to make the hot-melt rubber particles better bond.

Hot melt adhesives are known for their incredibly quick application times. The amount of time that hot melt adhesives are typically able to be used is approximately 15 seconds. As more and more modern production techniques, such as assembly lines, are put into use, the requirements for the amount of time that hot melt adhesives need to work are becoming shorter and shorter. For example, the manufacturing of books and speakers requires a work time of approximately five seconds for hot melt adhesives. The temperature has a significant impact on hot-melt adhesives. The hot-melt adhesive will begin to become more malleable once the temperature reaches a certain threshold. If the hot-melt adhesive is allowed to cool below a certain temperature, it will become brittle. Because of this, the choice of hot-melt adhesive has to take into account the fluctuating temperatures of the product's surroundings in its entirety.